3D metrology is a scientific study of physical measurement and is referred to a general field of precision measurement within industries. In its basic form, 3D metrology is used to accurately acquire an object’s geometrical data in 3 axes (X, Y, and Z). These measurements are often acquired through the use of different products such as coordinate measuring machines (CMMs), optical digitizers and scanners (ODSs), and others. 3D metrology systems are widely used in industries such as automotive, aerospace, energy & power, medical, and electronics to streamline the quality process and improve the manufacturing efficiency.

Visionary leaders are the leading market players in terms of developments such as product launches, innovative technologies, and adoption of growth strategies. These players have broad product portfolios that cater to most of the regions worldwide. Visionary leaders primarily focus on acquiring the leading market position through their strong financial capabilities and well-established brand equity.

There are many companies in the 3D metrology market that are largely dependent on their competitive R&D activities. Most of the dynamic differentiator players are classified under tier 2 and tier 3 companies, which have presence in various regions worldwide. The dynamic differentiators have lesser product offerings compared with visionary leaders, but have strong market.

Companies that are considered innovators should ideally have demonstrated substantial product innovations as compared to their competitors. They have innovative products and the potential to build strong strategies for their business growth to be at par with the visionary leaders. However, as compared to visionary leaders, they do not have a very strong growth strategy for their overall business development.

Emerging companies have niche product and service offerings. Their business strategies are not as strong as that of the established vendors. The emerging vendors include the new entrants in the market, emerging in terms of product portfolio and geographic reach, and require time to gain significant traction in the market.

As the market poses a moderate threat to new entrants in establishing their footprint, there are many players that are providing 3D metrology to diverse clientele groups worldwide. Quality control is an integral part of the production process as it helps in the smooth functioning of the production without incurring any extra cost. Under quality control and inspection, 3D metrology is used for alignment, CAD-based inspection, dimensional analysis, and machine calibration, among others. Manufacturers have a robust inspection process to control quality. Manufacturers use 3D metrology for accurate 3D scanning and inspection analysis to derive corrective action without slowing down the production. 3D metrology is also used to check misalignments that can cause machine downtime and affect machine performance. 3D metrology enables part inspection and dimensional analysis of machine parts to verify their accuracy and quality, which, in turn, helps eliminate costly scrap and need for rework. 3D metrology allows identification of defective parts and maintains strict quality standards. Quality control and inspection by 3D metrology systems are used in industries such as aerospace & defense, automotive, architecture & construction, medical, electronics, energy & power, and heavy machinery. Reverse engineering is a method of creating a 3D virtual model from an existing physical part for use in 3D computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), or other software. The process involves measuring an object and then reconstructing it as a 3D model. It helps in analyzing a product to identify its components and create representations of the product in another form. Reverse engineering is used in industries for 3D modelling, reconstruction from the scanned data, and data for digital simulation. Both CMMs and 3D scanners are used for reverse engineering. However, using 3D scanners is advantageous as the measurement of soft or fragile parts and detection of a large number of points can be done in a short time. Reverse engineering is used in areas such as turbine blades, car body parts, engine parts, gears, antennae, boat parts, and medical implants. It is important to assess the built quality of each component while making an assembly. Simulations and virtual assembly operations help manufacturers make design adjustments and calculate assembly positions and also determine the need for new adjustment parts. Virtual simulation is also changing the way animation is done in movies and video games. Instead of designing characters and sets, companies are now scanning real people to design characters. The virtual simulation also allows the media house to move the entire movie set to the desired location. However, in the case of manufacturing processes carried out in various industries worldwide, virtual simulations have been adopted for scanning and creating virtual models of various products before starting their manufacturing. This helps the manufacturer identify design errors, if any, in the product and also in avoiding wastage of manufacturing efforts.

Top 3D Metrology Solutions Companies - Quadrant Report

- Enterprise

- SME

- Startups

3D metrology is a scientific study of physical measurement and is referred to a general field of precision measurement within industries. In its basic form, 3D metrology is used to accurately acquire an object’s geometrical data in 3 axes (X, Y, and Z).

3D metrology is a scientific study of physical measurement and is referred to a general field of precision measurement within industries. In its basic form, 3D metrology is used to accurately acquire an object’s geometrical data in 3 axes (X, Y, and Z).

The 3D metrology market is expected to reach a valuation of USD 16 billion by 2024. The major factors contributing to the growth of the 3D metrology market are the highly accurate inspection owing to 3D data for modeling and analysis, focus on quality control, and increase in R&D spending.

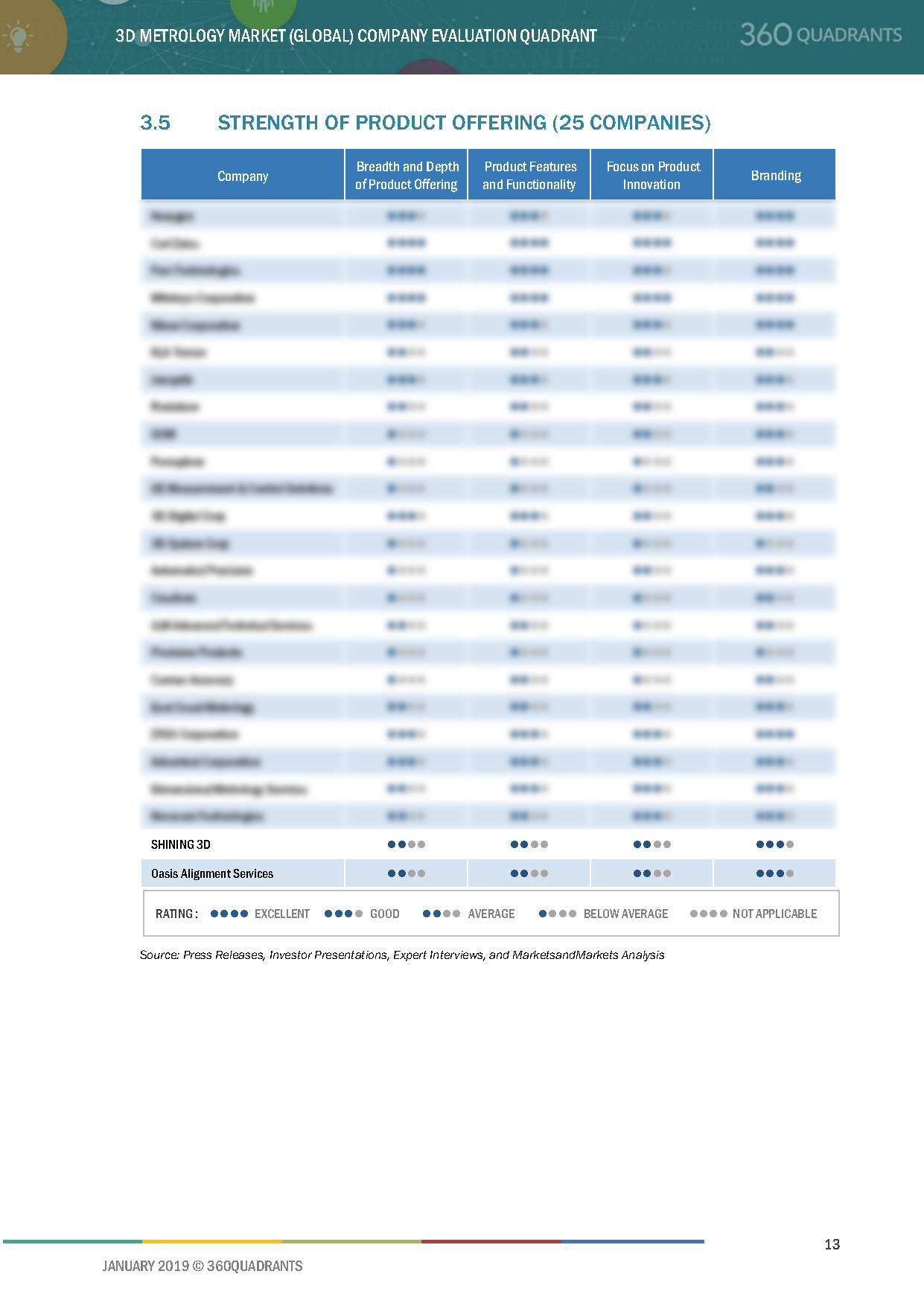

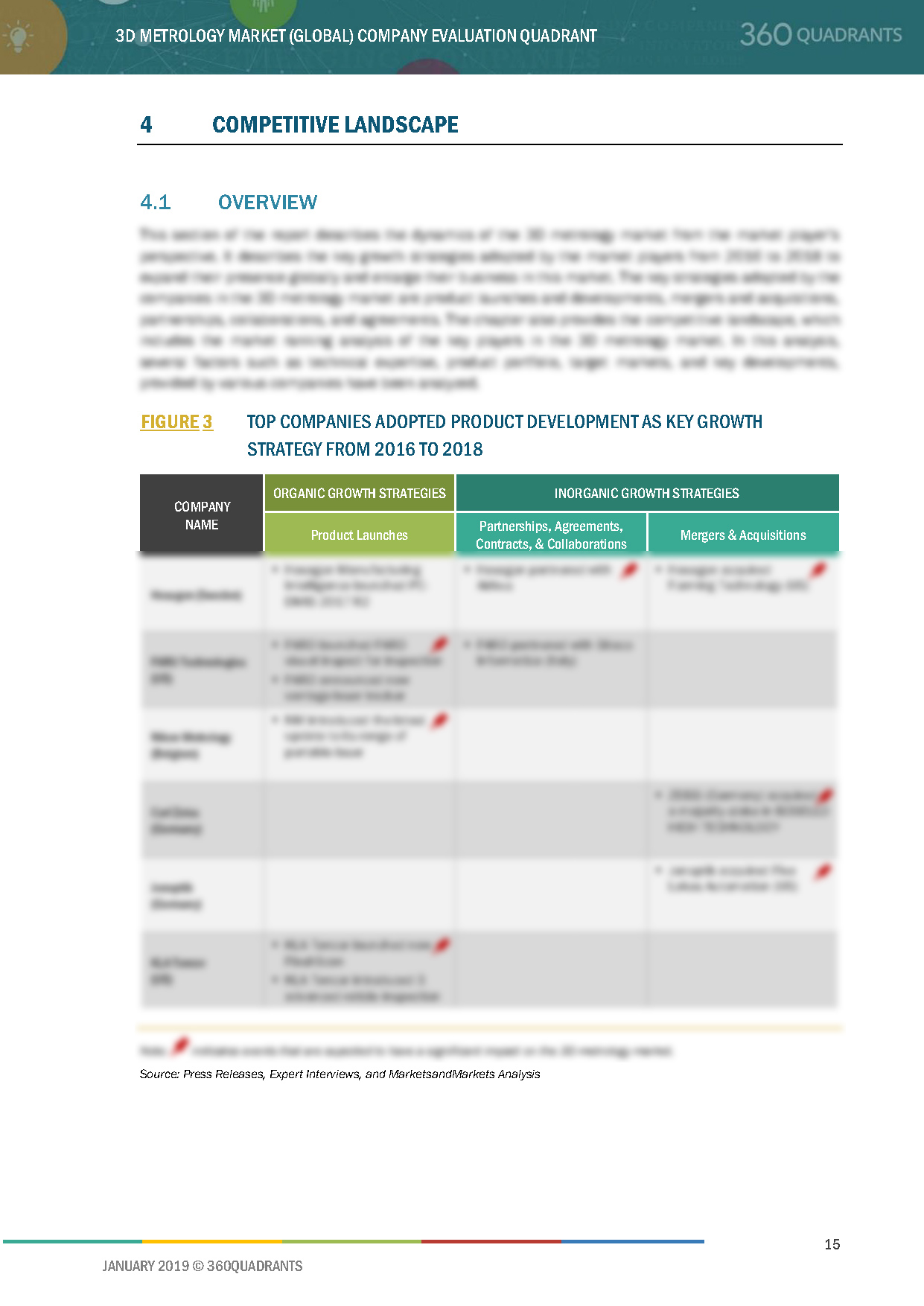

3D Metrology Solutions Providers - Quadrant report identifies and benchmarks the Top 3d Metrology Companies such as Hexagon AB (Sweden), Carl Zeiss AG (Germany), FARO Technologies (US), Mitutoyo Corporation (Japan), Nikon Corporation (Japan) and evaluates them on the basis of business strategy excellence and strength of product portfolio within the 3D metrology ecosystem, combining inputs from various industry experts, buyers, and vendors, and extensive secondary research including annual reports, company press releases, investor presentations, free and paid company databases. 3D Metrology Solutions Providers are rated and positioned on 2x2 matrix, called as ‘Company Evaluation Quadrant’, and identified as Visionary Leaders ( Top 3D Metrology companies ), Dynamic Differentiators, Innovators, or Emerging companies.

The report includes market-specific company profiles of 16 Top 3D Metrology companies and assesses the recent developments that shape the competitive landscape of this highly fragmented market.

3D Metrology Solutions Providers - Quadrant report identifies and benchmarks the 3D Metrology Leaders such as Hexagon AB (Sweden), Carl Zeiss AG (Germany), FARO Technologies (US), Mitutoyo Corporation (Japan), Nikon Corporation (Japan) and evaluates them on the basis of business strategy excellence and strength of product portfolio within the 3D metrology ecosystem, combining inputs from various industry experts, buyers, and vendors, and extensive secondary research including annual reports, company press releases, investor presentations, free and paid company databases. 3D Metrology Solutions Providers are rated and positioned on 2x2 matrix, called as ‘Company Evaluation Quadrant’, and identified as Visionary Leaders ( Top 3D Metrology companies ), Dynamic Differentiators, Innovators, or Emerging companies.

SAMPLES:

- Updated version of this Quadrant

- Different Company Evaluation Quadrant

- 'Startup Only' Company Evaluation Quadrant

- Region or Country specific evaluation

- Application or Industry specific evaluation ..Read More

- Submit a Briefing Request

- Question about our published research

- Request for evaluation of your organization for specific market

- Request for re-evaluation of Company Evaluation Quadrant ..Read More